DIVING EQUIPMENT CALIBRATION ,TESTING & AUDIT, LOAD TEST AND NDT SERVICES PROVIDED

We are a specialized inspection and testing company dedicated to ensuring the safety, reliability, and compliance of industrial equipment and structures. With expertise in Non-Destructive Testing (NDT), load testing, and equipment certification, we serve industries such as marine, construction, oil & gas, and manufacturing. Our certified technicians use advanced testing methods and calibrated equipment to deliver accurate, timely results—helping clients meet regulatory standards and prevent costly failures. Whether it's on-site testing or detailed reporting, we are committed to precision, safety, and excellence.

Diving equipment calibration, testing, and audit are essential processes to ensure the safety, reliability, and compliance of gear used in underwater operations.

-

Calibration: Adjusting and verifying instruments (like pressure gauges, depth gauges, and gas analyzers) to ensure they provide accurate readings according to recognized standards.

-

Testing: Functionally checking diving equipment (e.g., regulators, tanks, BCDs, dive computers) to confirm they work properly under simulated or controlled conditions.

-

Audit: A systematic inspection or review of equipment records, maintenance logs, and procedures to ensure everything complies with safety standards, manufacturer guidelines, and regulatory requirements.

Magnetic Particle Inspection (MPI) services offer professional testing to detect surface and near-surface defects in ferromagnetic materials.

-

On-site or in-house inspection of components like welds, pipes, structural steel, or machinery.

-

Detection of cracks, seams, laps, porosity, or fatigue in metals.

-

Preparation and cleaning of test surfaces.

-

Magnetization and application of magnetic particles (wet or dry method).

-

Interpretation and reporting of results with clear defect identification.

-

Compliance with standards ( ASME, ISO, AWS) for quality assurance.

Marine load test services offer professional testing to verify the strength, safety, and performance of lifting equipment and structures used in marine environments.

-

Load testing of cranes, davits, winches, A-frames, lifting slings, and pad eyes on ships, offshore platforms, and docks.

-

Use of certified weights or water bags to simulate actual working loads.

-

Measurement and verification that equipment can handle the rated load without deformation or failure.

-

Inspection and certification in compliance with industry standards (IMO, SOLAS, DNV, ABS).

-

Detailed reporting and issue of load test certificates.

Dye Penetrant Inspection (DPI or PT) services offer a simple and effective method for detecting surface-breaking defects in non-porous materials such as metals, plastics, and ceramics.

-

Surface preparation to remove dirt, oil, or coatings.

-

Application of visible or fluorescent dye penetrant to the test surface.

-

Dwell time to allow the dye to seep into cracks or flaws.

-

Excess dye removal followed by applying a developer to draw out trapped dye.

-

Inspection under visible or UV light to reveal any defects like cracks, pinholes, or porosity.

-

Reporting and certification based on inspection standards (ASME, ASTM).

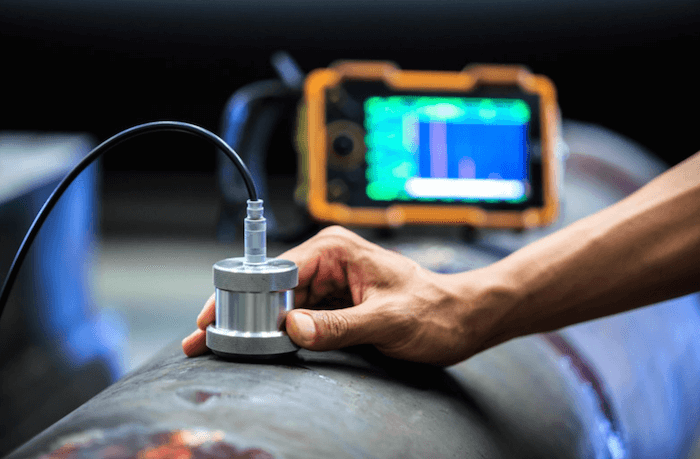

Offshore Ultrasonic Testing (UT) services provide non-destructive inspection of materials and structures on offshore platforms, vessels, and subsea installations to detect internal flaws and measure material thickness.

Detection of internal cracks, corrosion, and weld defects using high-frequency sound waves.

-

Thickness measurements of pipes, tanks, and structural components to monitor corrosion or erosion.

-

Inspection of topside and subsea assets, including risers, pipelines, pressure vessels, and structural welds.

-

Advanced UT methods (Phased Array, ToFD) for detailed flaw imaging and sizing.

-

Certified reports and data analysis for maintenance planning and regulatory compliance.

Radiographic Testing (RT) services offer non-destructive inspection to detect internal defects in materials and welded joints using X-rays or gamma rays.

Imaging of internal flaws such as cracks, porosity, slag inclusions, or voids in welds, castings, and components.

-

Use of X-ray or gamma ray sources to penetrate materials and capture images on film or digital detectors.

-

Evaluation of image quality to identify and assess the severity of defects.

-

Onshore or offshore inspection of pipelines, pressure vessels, structural welds, and more.

-

Certified reporting and compliance with international standards (ASME, ISO, API).

WE OFFER DIVING EQUIPMENT CALIBRATION ,TESTING & AUDIT, LOAD TEST AND NDT SERVICES FOR OUR CLIENTS

We offer a complete range of services—from diving equipment calibration and audits to load testing and non-destructive testing—streamlining your compliance process under one trusted provider.

All testing and calibration are performed by certified technicians using traceable, industry-approved equipment, ensuring accurate results and maximum safety.

We understand the unique demands of commercial diving operations and provide meticulous audits and maintenance testing tailored to IMCA and international standards.

Our mobile teams are equipped to perform inspections wherever you operate—onshore, offshore, or in remote locations—minimizing downtime and keeping your operations running.

You receive detailed, professional reports backed by international standards (ISO, IMCA, ASME, etc.), helping you meet legal and client requirements with confidence.

WHY CHOOSE PMSB

✅ IMCA & ISO Compliant – We follow strict international standards for safety and accuracy.

🔧 Specialists in Diving Equipment – Trusted for precise calibration and thorough audits of life-support systems.

💪 Certified Load Testing Experts – Reliable testing for lifting gear, structures, and marine assets.

📍 On-Site & Offshore Ready – Mobile teams equipped to serve you anywhere, anytime.

📋 Clear, Professional Reporting – Fully documented results to meet compliance and client requirements.

OUR EXPERT TEAM

Our team is made up of highly trained, certified professionals with deep expertise in diving equipment testing, calibration, audit, and load testing services. Each technician is qualified to perform inspections in line with IMCA, ISO, and other international safety standards, ensuring your equipment and systems are compliant, reliable, and safe.

With backgrounds in commercial diving, offshore operations, engineering, and safety compliance, our personnel understand the real-world demands of your industry. Whether calibrating critical life-support systems, auditing dive spreads, or conducting structural and lifting gear load tests, our team brings precision, integrity, and technical excellence to every job.

We are committed to delivering results you can trust—with clear reporting, minimal operational disruption, and a safety-first mindset at all times.